When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

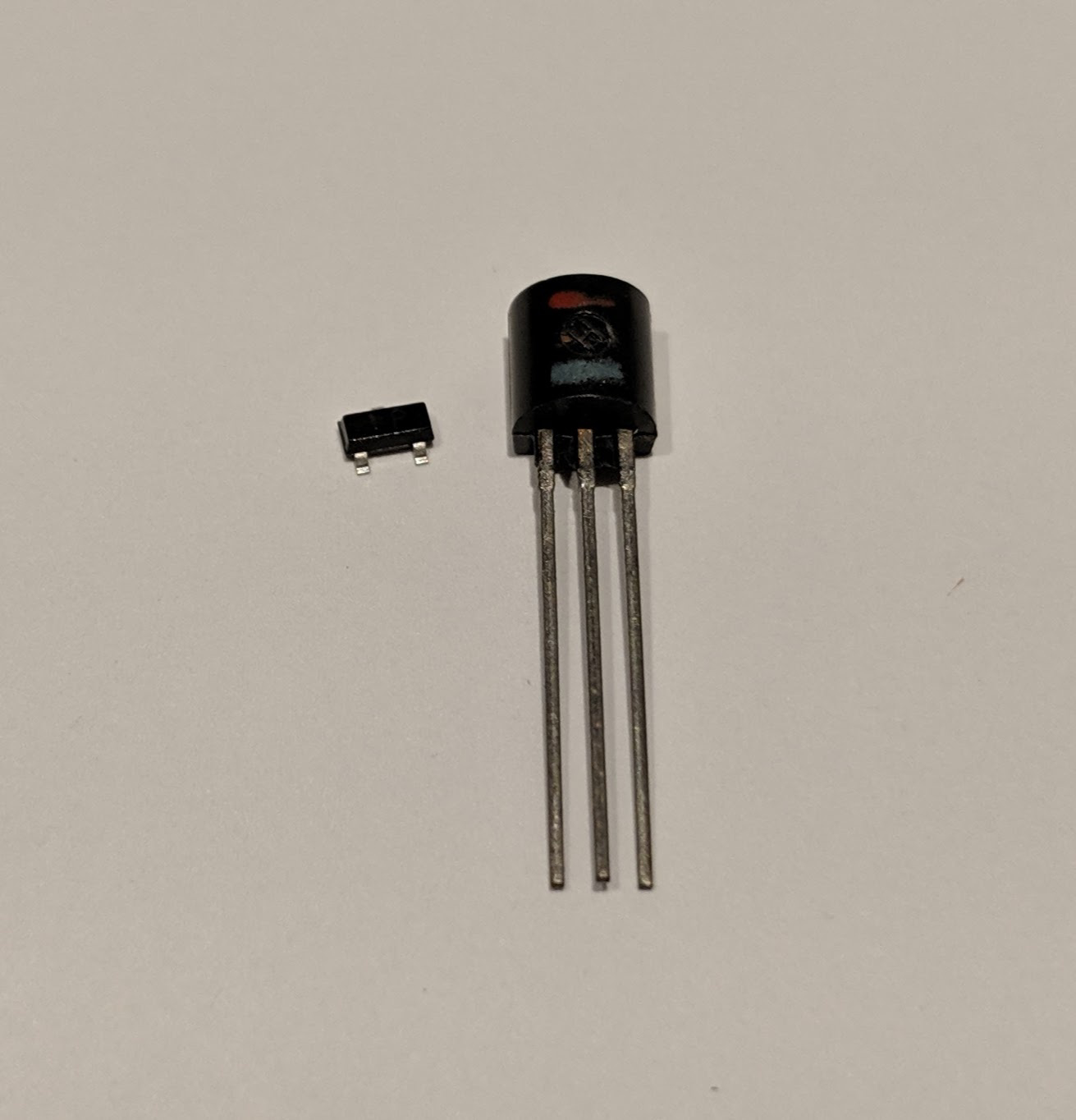

A pair of 2N2222 transistors, one SOT23 and one TO-92.

Are there good instructions out there for people using cheap irons to solder these small components? How does one get into soldering now with a hot plate vs hand iron considering that these components have a much higher learning curve than the older larger parts ?

The cheap soldering irons are tricky because heat distribution is crucial. If your iron is not at the right temperature and the heat transfer is not uniform you can fry a component instantly, specially the smaller components. you need a soldering iron with temperature dials at bare minimum

If you want to do really low investment hot plate soldering, some solder paste, good tweezers and a frying pan with some sand in it is probably good. Just keep an eye on it while heating, and stop when the solder melts

I haven’t looked into it, but I guess I would start at instructables.com or maybe YouTube

I’m working on making some videos to show what can be done with basic equipment even with modern, small components. Maybe I should add some soldering 101 type videos? I can add them to my YouTube channel for my 6 subscribers. Heh.

EDIT: 9! 9 subscribers! Pretty soon I’ll be able to quit my day job and live off my YouTube channel.

I’m going to sub too!! But I need a link!

I may not be able to handle the pressure.

https://www.youtube.com/@MapleEngineering

Subbed !

Noice. Thanks.