Hi all,

In an effort to liven up this community, I’ll post this project I’m working on.

I’m building a solar hot water controller for my house. The collector is on the roof of a three-storey building, it is linked to a storage tank on the ground floor. A circulating pump passes water from the tank to the collectors and back again when a temperature sensor on the outlet of the collector registers a warm enough temperature.

The current controller does not understand that there is 15 metres of copper piping to pump water through and cycles the circulating pump in short bursts, resulting in the hot water at the collector cooling considerably by the time it reaches the tank (even though the pipes are insulated). The goal of my project is to read the sensor and drive the pump in a way to minimise these heat losses. Basically instead of trying to maintain a consistent collector output temp with slow constant pulsed operation of the pump, I’ll first try pumping the entire volume of moderately hot water from the top half of the collector in one go back to the tank and then waiting until the temperature rises again.

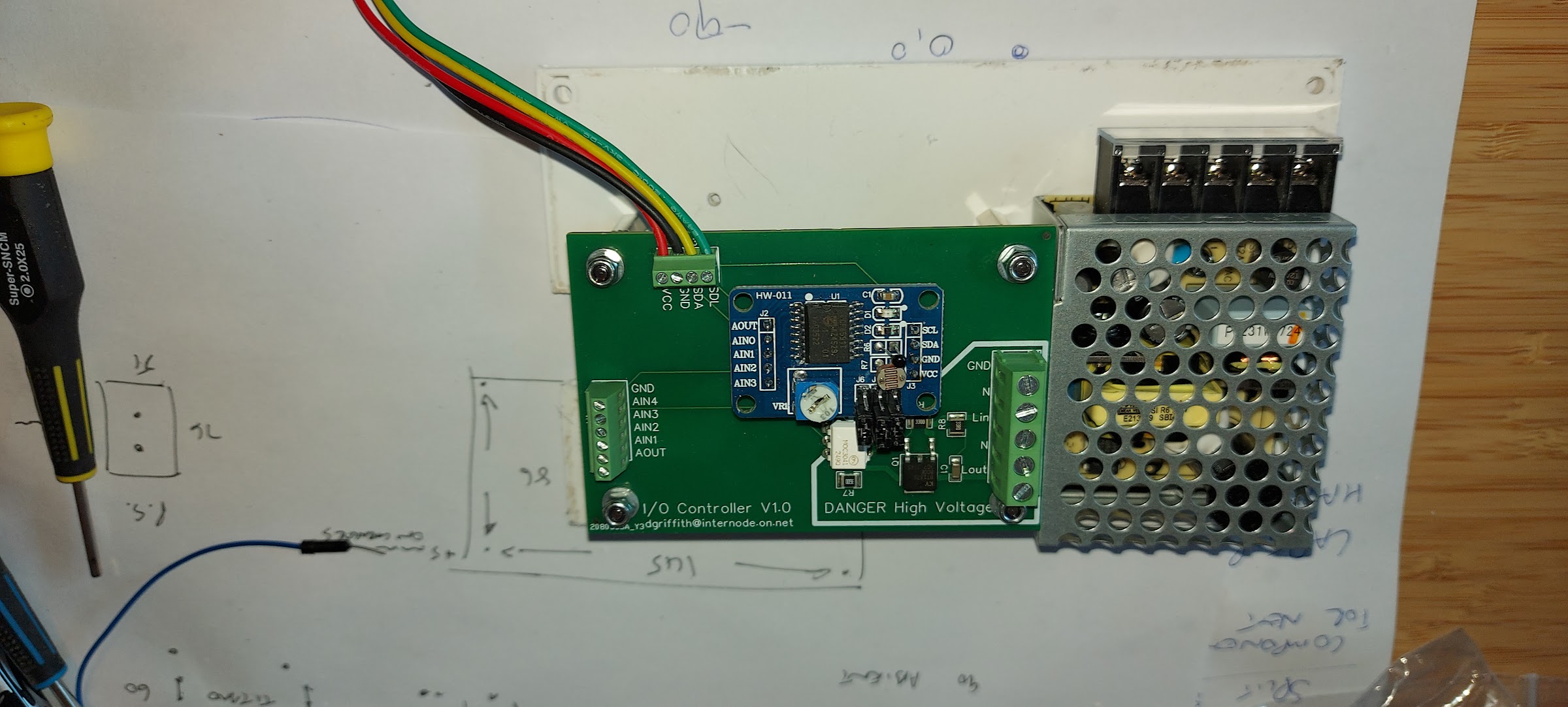

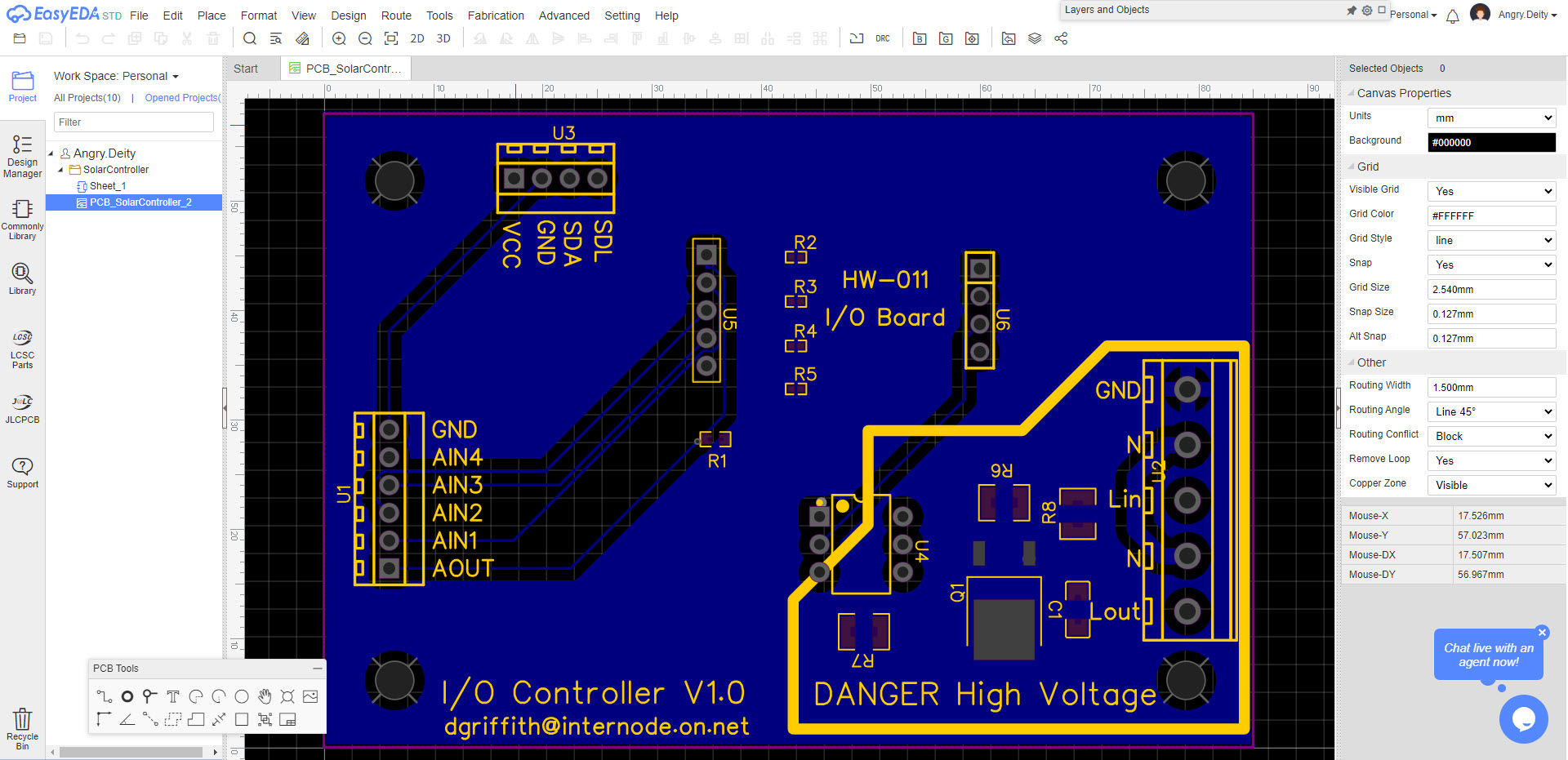

I am using an Adafruit PyPortal Titano as the controller, running circuitpython. For I/O I am using a generic ebay PCF8591 board, which provides 4 analog input and a single analog output over an I2C bus. This is inserted into a motherboard that provides pullup resistors for the analog inputs and an optocoupled zero crossing SCR driver + SCR to drive the (thankfully low power) circulating pump. Board design is my own, design is rather critical as mains supply in my country is 240V.

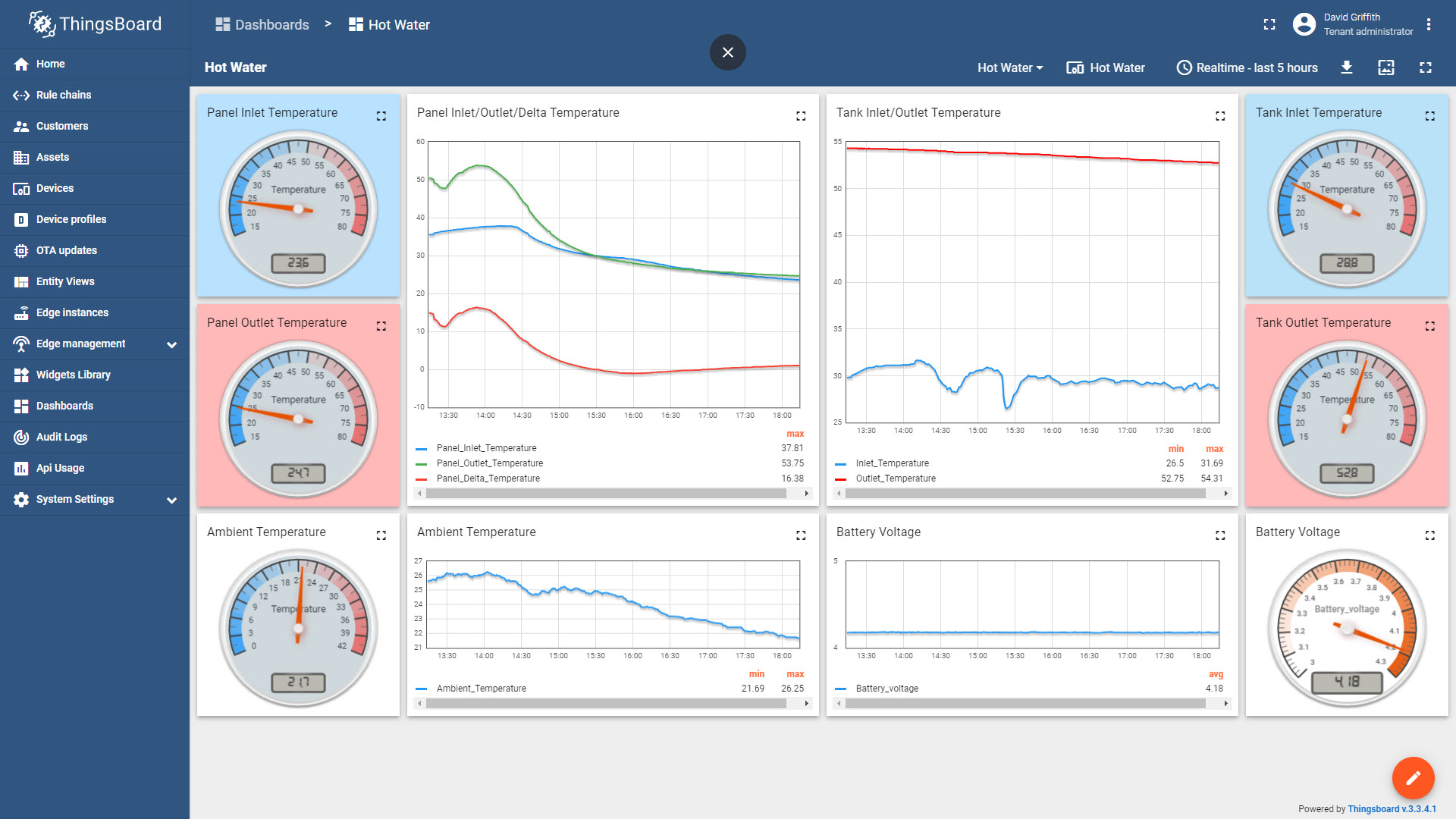

The original sensors are simple NTC thermistors, one at the bottom of the tank, and one at the top of the collector. I have also added 4 other Dallas 1-wire sensors to measure temperatures at the top of tank, ambient, tank inlet and collector pump inlet which is 1/3rd of the way up the tank. I have a duplicate of the onewire sensors already on the hot water tank using a different adafruit board and circuitpython. Their readings are currently uploaded to my own IOT server and I can plot the current system’s performance, and I intend to do the same thing with this board.

The current performance is fairly dismal, a very small bump of perhaps 0.5 - 1 deg C in the normally 55 degree C tank temperature around 12pm to 1pm, and this is in Australia in hot spring weather of 28-32 degrees C.(There’s some inaccuracy of the tank temperatures, the sensors aren’t really bonded to the tank in any meaningful way, so tank temp is probably a little warmer than this. But I’m looking for relative temperature increases anyway)

Right now , the hardware is all together and functional, and is driving a 13W LED downlight as a test, and I can read the onewire temp sensors, read an analog voltage on the PCF8591 board (which will go to the NTC sensors), and I’m pulsing the pump output proportionally from 0-100 percent drive on a 30 second duty cycle, so that a pump drive function can simply say “run the pump at 70 percent” and you’ll get 21 seconds on, 9 seconds off. Duty cycle time is adjustable, so I might lower it a bit to 15 or 10 seconds.

The next step is to try it on the circulating pump (which is quite an inductive load, even if it is only 20 watts), and start working on an algorithm that reads the sensors and maximises water temperature back to the tank. There are a few safety features that I’ll put in there, such as a “fault mode” to drive the pump at a fixed rate if there is a sensor failure, and a “night cool” mode if the hot water tank is severely over temperature to circulate hot water to the collector at night to cool it. There are the usual overtemp/overpressure relief valves in the system already.

All this is going in a case with a clear hinged cover on the front so I can open it and poke the Titano’s touchscreen to do some things.

Right now I am away from home from work, so my replies might be a bit sporadic, but I’ll try to get back to any questions soon-ish.

A few photos for your viewing pleasure:

The I/O and mainboard plus a 5V power supply mounted up:

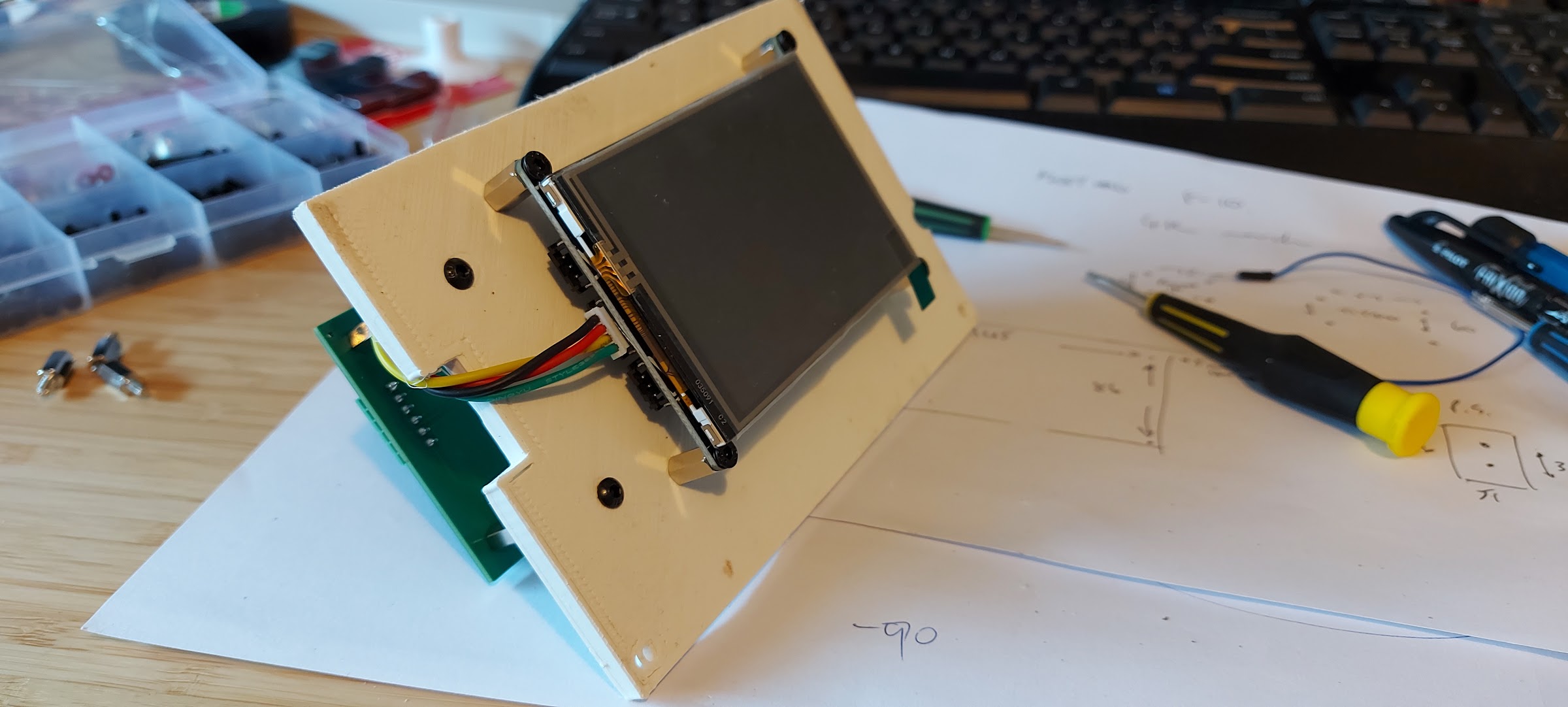

The front of the panel, showing the Pyportal:

Thingsboard display showing readings from the current system:

Mainboard PCB design and construction via EasyEDA:

Just as a PCB designer, make sure that you spec out the 240V voltage neutral and live copper trace width to the current going through them. For example, at 10 amps, those traces look much too small. Is it going to be in a high humidity environment? The spacing between traces also should be bigger for creepage/clearance reasons.

Cool project though!

Yes the traces are pretty light for those kinds of currents, and I did have some concerns on the track spacing around the SCR and the screw terminals. The fatter tracks use a spacing for 240v that I looked up online.

Humidity here isn’t “tropical” as such, the board will probably get a coat of lacquer anyway.

The circulating pump is rated at 240v/20 watts (so not much current when it’s running steady state), and the SCR I’m using is good for a few amps of continuous current draw with a fairly high surge current. The SCR has minimal heatsinking so it will go first in extended high current situations, there’s going to be a panel mount fuse before all of this that I’ll probably set to 2 amps or so.

The zero-crossing SCR controller I’m using “should” prevent switching on the pump at the peaks of the mains cycle so max current should just be the initial stall current from the motor before it gets up to speed.

The pump is an induction motor so the only concern I’ve got is false triggering of the SCR and being unable to turn the pump off once triggered. I used an example snubber circuit from the data sheet of the zero crossing controller and of course they said “your milage may vary”.

OK this is interesting, but also differs. If I have read correctly, you’re circulating the water in the system as a whole.

I’m also using a solar setup, but I’m using a serpentine coil running a separate coolant liquid. The coolant is used since winter goes from -10 to minimim -20 degrees celsius.

What are your coldest months like?

At my latitude, never below 8 or 9 degrees C in winter. Maximum temperature is about 35 or 36 degrees C in summer.

Older systems here were simple thermosyphon designs on the roof with the holding tank closely coupled directly above the collectors and they were quite effective.

My system has a 330 litre mains pressure hot water tank, with the usual cold and hot fittings bottom and top. There is a third inlet about 1/3rd of the way up the tank, and a little bit above that is a heater element and a controlling thermostat. The lower third of the tank is circulated out via the cold inlet and up through the collector by the pump, which can do about 300 litres an hour. Hot water returns from the collector at the 1/3rd location, and rises to the top of the tank via stratification. The copper pipes to and from the collectors are 1/2" and are insulated, but their surface area to volume ratio is quite large and heat is easily lost over the 15 or so metres of pipework.

On sunny days I can see the inlet temperature at the bottom of the tank slowly rise from approx 20-25 degrees C to 30-35 degrees C as the bottom third circulates, the hotter water rises to the top to give the small temperature rise I can see at the top of the tank and the warm water layer slowly lowers towards the bottom of the tank.

Essentially I want a higher temperature returned to the tank, which I suspect can rather paradoxically be done by increasing the circulation rate when running the pump, peaking the collector temperature higher with the pump off then dumping that back to the tank rapidly, rather than the current controllers method of pulsing the pump and slowly circulating it to maintain a moderate collector temperature and losing the heat in the lines.

I have the service manual for the controller and it mentions frost protection, where it will circulate warmer water back to the collectors in low temperatures, but this would be insufficient for your colder climate.

At some stage I would also like to control the heater element, it runs on an off peak circuit which is switched by the electricity company when it suits them, so it is cheaper to run. It also means that it regularly “tops up” the top 2/3rds of the tank temperature, which negates the solar contribution a fair bit. I would like to be able to disable that top up if the system can sense adequate heating from the collectors, but that requires switching control to a 3kW element, and something I will leave alone for now.

Hmm, the heater element being controller disregarding your will is a bit of a bummer.

Thanks for clarifying, so you are indeed circulating the water itself, it’s not a separate line used as a heater. In this case you really are at the mercy of either your pump, pipe length, ambient temperature, insulation and/or sun intensity.

Have you monitored the temperature at the panel on the roof itself? Also, what type of insulation are you running on those pipes?

It’s generic foam pipe insulation, approximately 3/4" thick.Originally there was also a 3-4 meter section of pipework from the collector output to inside the roof that was completely uninsulated, I’ve gotten that sorted.

I bought the place a couple of years ago and after replacing the seized circulating pump early last year I was pretty disappointed with the system’s performance.

At that point I put onewire sensors on the tank and lines on the ground level and measured it for a few months and didn’t see much heating at all from the collector.

I couldn’t get to the collectors for a long time, not having a three storey ladder, but I got suspicious after sunny + windy days resulted in very little heating. Finally got up there about three months ago to discover that bare section of pipe and insulated that.

Collector temperature I haven’t measured using the original analog sensor yet, I just let the original controller do its thing to get a baseline. But currently in a “warm” Australian spring the maximum outlet temperature at ground level is a brief peak of about 65 degrees C at around 1pm. Going off the circulation rate of the pump it’s probably 40 litres of water at that temp before it starts dropping back down in the afternoon.

Insulating that bare section of pipe improved performance but it’s still not fantastic, so now it’s time to drive the pump with my own algorithm and see if I can improve things.

Yeah, that seems like a good way to go. 65 degrees at ground level is what I’d also expect. My assumption up top would be close to 90/95 degrees. Driving the pump more often would be interesting.